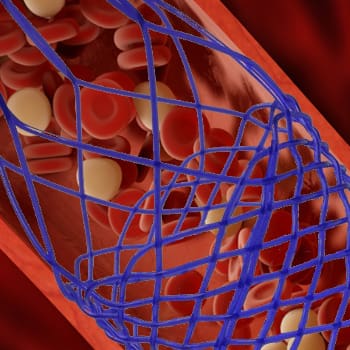

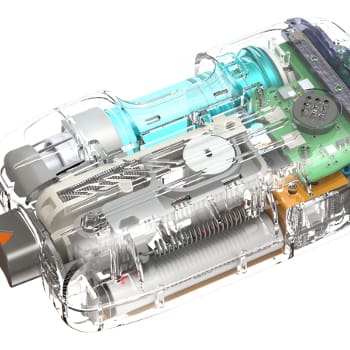

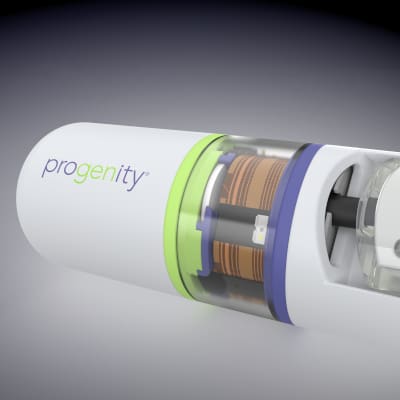

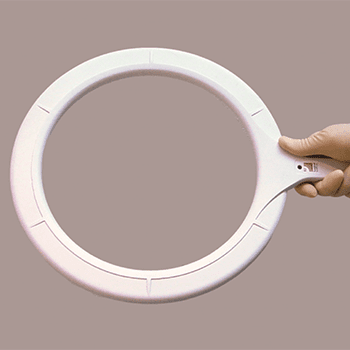

Since 2010, NOVO has been contracted for numerous engagements to add feature improvements to an intragastric balloon and balloon inflation system, including balloon and valve development, inflation system design, and systems architecture. This medical device is designed to assist weight loss by partially filling the stomach. The balloon has a radio-opaque sealing valve and is encapsulated within a USP-grade gel cap, enabling delivery via a catheter. Once there is radiographic confirmation of successful placement in the stomach, the balloon is inflated to a defined pressure using a custom inflation system. The catheter is detached and retrieved, leaving the gas-filled balloon in the patient’s stomach. The therapy prescribes up to 3 balloons during a 6-month period.

For the inflation system improvements, NOVO provided the client with design, verification, and validation services to support submission of a pre-market approval (PMA) application to the FDA. Since timing was sensitive, NOVO developed solutions that fit within existing designs without incurring significant changes to critical subsystems like the PCBA, mechanical enclosures, or overall size.

Concept Development, Feasibility, and Planning

Using an established process for product development, NOVO performed concept development, feasibility analysis, and detailed project planning for this medical device. Utilizing in-house expertise in the areas of pressure regulation and control systems, NOVO evaluated the feasibility of several design options to enhance functionality. NOVO researched key components, applicable technologies, and manufacturing processes to ensure an optimized design. NOVO and the client held multiple reviews and worked closely within the client’s design control system to determine the best path forward. NOVO subsequently developed an execution plan to incorporate selected modifications, many of which included contributions from mechanical engineering, electrical engineering, and software engineering.

Detailed Design, Design Verification, and Design Validation

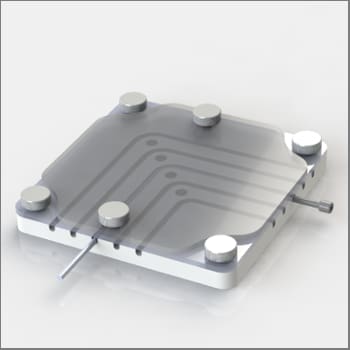

NOVO optimized a tightly constrained pressure manifold with little or no impact to existing components, performed power consumption analyses, and implemented ESD solutions for air discharge and direct contact requirements of IEC 60601-1-2. These are some examples of the many contributions to system design. All solutions fit with existing manufacturing capabilities.

NOVO’s software contribution included setting up the build environment, code development, peer reviews, static analysis configuration, and unit test framework; we also supported establishment of software requirements specifications and software architecture design. NOVO worked within the client’s design control system to support their code development and refinement. NOVO performed many elements of software design verification for the deployment device, including issues investigation, implementation of code revisions, and contributed to software/requirements/risk/protocol documentation. All solutions met final design validation criteria.

As a result of NOVO’s engagement on this project, the system has been successfully iterated with more automated control, providing improved ease of use for the clinician during deployment.