TEST, PROCESS, LAB, QC, AND ASSEMBLY AUTOMATION

Automation Applications

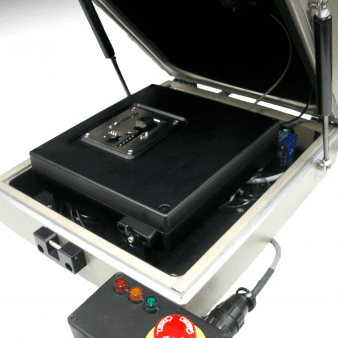

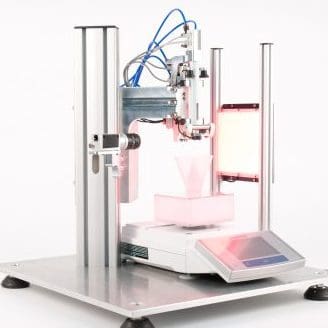

NOVO provides custom automated equipment development as part of product development efforts and as a stand alone service. Custom equipment includes automated test equipment (ATE), lab automation, process automation, quality control jigs and fixtures, and specialized assembly automation. NOVO’s ability to develop automated manufacturing and quality control equipment in parallel with product development accelerates verification and design transfer activities. This equipment is often transferred to contract manufacturers or used on pre-production assembly lines prior design transfer.

Automation Design Considerations

NOVO engineers with automation, machine design, and industrial controls experience will identify the appropriate system architecture for the application with consideration for the operator profile, use environment, machine guarding, reliability, serviceability, qualification requirements, configurability, and throughput. We then take advantage of our in-house CNC machine shop, electro-mechanical assembly technicians, programming, and procurement staff to bring custom machines online quickly.

NOMADC™ Modular Device Controls

We have developed a comprehensive suite of firmware and hardware building blocks to accelerate the development of automation. These pre-existing, pre-tested modules enable rapid implementation of automation for any automated test, quality control, or assembly application. A plug and play, industrial quality automation system for performance testing during product development provides an objective measure of performance through each design iteration. NOMADC firmware and hardware is production ready in modular form, or re-layout onto a single board for low to medium volume instruments.

Automation Support Services

Custom equipment/custom automation projects are accompanied by a complete documentation package, BOM, schematics, and operating instructions. Factory and site acceptance testing, equipment qualification, and gage R&R studies are conducted as required. Telephone and video support is provided to our customer’s technicians to minimize the need for onsite support.

NOVO understands the value of automation and product development expertise on the same team. The interaction between product designers and automation designers promotes both design for manufacturability and more effective test, quality control, assembly, and process automation.

Compliance

Our automation systems comply with industry standards, safety standards, and regulatory standards as applicable or requested by our customers.

Selected Custom Equipment Projects And Expertise

- Silicon wafer coating system

- Microplate-cleaning robot

- Microplate heater

- Gigamatrix ultra-high-throughput enzyme screening system

- Agricultural sample reformatting robot

- Golf club assembly automation

- Mobile biohazard waste treatment equipment

- Fluidized bed centrifuge

- Reagent dispensing equipment

- Needle hub assembly and proof testing

- Automated test systems for numerous medical devices